Industrial Manage printed circuit board (PCB) assembly is in the Main of recent production and automation techniques. As industries try for greater effectiveness, precision, and reliability, improvements in PCB assembly Perform a pivotal part in meeting these calls for. This document explores the rising tendencies and groundbreaking innovations shaping the way forward for industrial Regulate PCB assembly, featuring insights into how know-how is revolutionizing this critical area.

Table of contents:

The Evolution of Industrial Management PCB Assembly

Superior components in PCB Assembly for Industrial purposes

problems and methods in higher-effectiveness Industrial PCB Assembly

The Evolution of Industrial Command PCB Assembly

Industrial Manage PCB assembly has undergone considerable transformations lately, driven by breakthroughs in technological know-how plus the increasing demand from customers for prime-overall performance and trustworthy Digital solutions. The evolution of producing processes, like floor mount technologies (SMT) and through-gap know-how (THT) assembly, continues to be pivotal in reaching higher effectiveness and precision. corporations like Mango Remedy, noted for their detailed PCB assembly services, have leveraged chopping-edge abilities, like multi-layer PCB assembly and Sophisticated tests strategies, to meet rising industrial prerequisites. With their capacity to develop as many as five million placements each day and produce PCBs in as minor as two days, companies have embraced streamlined workflows and progressive approaches. Automation and robotics in PCB assembly emphasize breakthroughs in the sphere. automatic high quality checks, AOI inspections, and X-Ray systems lower faults, guaranteeing precision and regularity. personalized alternatives like box builds and wire harness assemblies have expanded prospects for industrial Handle PCBs. Balancing cost efficiency with high effectiveness, present day PCB assembly is driving a upcoming the place innovation meets practicality.

State-of-the-art components in PCB Assembly for Industrial apps

the selection of materials used in PCB assembly is usually a crucial Think about determining the performance, longevity, and dependability of industrial Regulate techniques. Highly developed components including large-Tg laminates, ceramics, and polyimides are now additional common for dealing with the thermal and mechanical stress linked to demanding environments. Copper, with its superb conductivity, stays a typical selection, but the latest innovations have introduced alloys and composites to support distinctive use-situation necessities. Mango Option’s PCB assembly products and services present finishes like HASL, immersion tin, and electroless gold plating, tailored for several industrial purposes. These coatings enhance electrical functionality and guard circuit boards from oxidation and degradation. resources like solder mask, silkscreen, and laser-cut stainless-steel stencils even further boost longevity. The rise of eco-pleasant materials is additionally shaping the market, with producers adopting guide-free soldering and sustainable packaging. significant-overall performance products and eco-friendly processes are redefining the opportunity of industrial Handle PCB assemblies.

worries and Solutions in significant-overall performance Industrial PCB Assembly

Even with substantial developments, difficulties continue being in industrial Regulate PCB assembly. vital problems contain acquiring dependable efficiency throughout manufacturing cycles when retaining charges competitive. ingredient miniaturization, raising circuit complexity, and thermal management include further strain to assembly processes. To tackle these, corporations like Mango Remedy use high-good quality factors, rigorous quality Command, and specialized screening like ICT and software package burn up-in assessments. In addition they source choices or pin-to-pin equivalents for uncommon or high-priced factors, making sure Charge-effectiveness and avoiding production delays. Customization is another challenge, as industrial purposes normally demand personalized PCBs. Mango Resolution satisfies this have to have with flexible board assembly and prototype manufacturing as compact as 5 parts, creating customized methods accessible to equally startups and set up enterprises. Scaling manufacturing without the need of sacrificing good quality is an additional problem. Mango Alternative’s robust output potential, coupled with automated assembly processes, guarantees performance and precision, providing responsible remedies for swiftly rising industries.

The global shift in direction of industrial control PCB assembly State-of-the-art industrial Manage programs relies closely on innovation in just PCB assembly. Combining successful processes, reducing-edge resources, and adaptive options assures business leaders like Mango Option are equipped to satisfy the demands of this rapid-evolving sector. for all those trying to get reliable and productive PCB assembly providers, organizations at the forefront of innovation, for instance Mango Solution, present highly State-of-the-art PCB capabilities that permit companies to remain aggressive and travel success of their operations.

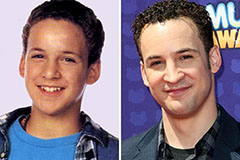

Ben Savage Then & Now!

Ben Savage Then & Now! Brian Bonsall Then & Now!

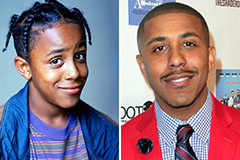

Brian Bonsall Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!